Behind the scenes: Gaggenau's Lipsheim factory

When considering a factory, it's rare that artisanal craftsmanship springs to mind. Yet, a visit to the Gaggenau factory in Lipsheim completely removes the former connotations of heavy machinery and smoky industrial plants…

Words Catherine McMaster

Photography Ben Reeves

Enveloped in a mellow, mechanical buzz, the factory is filled with a throng of people, all dressed in a utilitarian, navy ensemble. Their faces have a look of intense concentration, yet there’s an easiness to them, too. They evidently enjoy the company and surroundings.

The factory is in Lipsheim, France, and is just a 10-minute drive from the German border. The 1930s structure is comprised of high ceilings and natural light. Ambiguous machinery and metalwork is passed from one hand to another, and it’s only occasionally you glimpse the finished product: an oven or coffee machine.

The industrial revolution of 1760–1840 began in Britain, and soon spread across the continent. Factories sprang up and offered agrarian communities the chance to evolve into urban trade centres. By 1900, Germany had the biggest economy in Europe, thanks to its booming industry. In 2010, Germany’s Ruhr region, which is synonymous with steel works, coal mines and blue-collar jobs, was voted Europe’s Capital of Culture.

Factories are pigeonholed as highly unemotional, sterilised and mechanical spaces. Images of formulaic production lines cloud our judgement when the word ‘factory’ springs to mind. Yet, how many of us have stepped inside and visited a working plant? How many of us have spoken to the workers? Perhaps not so many.

The image of the factory is a nostalgic one. Smoke billows from great shot towers, automated production lines and a maze of vast machinery. It’s a picture that doesn’t inspire romantic connotations, but is a symbol of a bygone and pulsating industrial past.

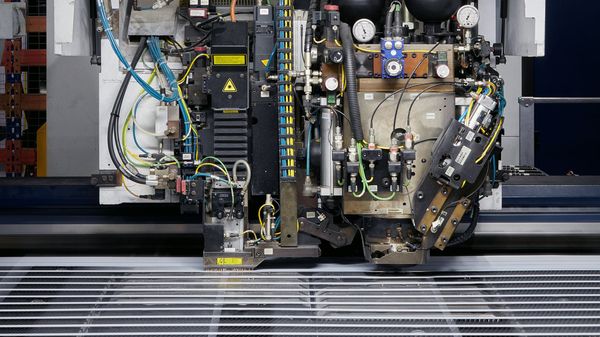

From the outset, the Gaggenau factory sets itself apart. Firstly, it’s an industrial manufacturing site, not an automated one.

‘We do more handwork than other factories,’ says Jörg Neuner, who’s responsible for the Gaggenau Brand Centre at Lipsheim. ‘People are often surprised when they visit at the personal touches on show here, as well as the manufacturing capabilities.’

The Gaggenau plant has approximately 350 workers in production. Each one is trained on multiple products and processes, meaning they’re highly skilled within many areas of the production line. The factory produces all of Gaggenau’s kitchen appliances, including the coveted 90cm oven. This iconic and distinctive piece is predominantly hand-built and takes two people one hour to create.

In the whole factory, there is only one automated product, the TruMatic 6000. On every other machine (of which there are many) people feed material in or work by hand. The result is a pulsating buzz, and an example of the harmonious working relationship between man and machine.

This is personified in the ‘clean room assembly’, the only one inside BSH (Gaggenau’s parent company). Within this confined space, a microcosm within the factory at large, workers have to wear white suits and face masks. Inside this futuristic haven, five Gaggenau factory workers meticulously and carefully build each TFT touch display.

‘There is so much effort in this process,’ Jörg explains, ‘as it’s the first touch point for a potential client.’

The entire factory is a diligently structured and conscientious place which straddles the outskirts of Lipsheim. Standing in stark contrast to its bucolic surroundings, the factory has been on this site since the 1930s. The original building still stands.

The factory manufacturers 205,000 appliances every year. Each day, seven trucks come to load up and deliver the goods to customers. This is a big achievement for a unit that only manufactures what is ordered and only produces what is sold. Gaggenau is the smallest factory inside BSH, but it also boasts the widest diversity of products.

However, what really sets the place apart is its highly personalised and authentic tone. The workers are passionate, involved and highly skilled. Their passion for the product and the brand is infectious.

It’s a highly stylised and disciplined arena, yet not an automated unemotional environment either. It’s a factory that retains its humanity and celebrates the modernisation of machinery and industry, while still honouring an artisanal past.